| next newest topic | next oldest topic |

| Author | Topic: vacuum sizing |

|

mitch Senior Member Posts: 10 |

Hello. I am currently free extruding a Polyethylene tube (diameter 0.410", wall thickness 0.045") and having allot of trouble getting it into spec and getting it to a round shape. I have the use of a vacuum tank and would like to try this tube on the tank. is there a formula I can use (or rule of thumb) to determiner the diameter of my sizing rings. the vacuum tank is a killion one. thank you IP: Logged |

|

Tom C Moderator Posts: 408 |

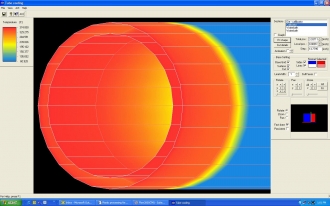

The trick with size calibration is to try and match the product size while the polymer is cooling. Polymers shrink as they cool, so the calibration starts larger and transitions to the desired size. You must figure out how fast the transition occurs. That will be related to the cooling rate and the shrinkage characteristics of the resin. This is not an easy problem. The company I represent, Compuplast, makes software to assist in these determinations. Sample of tube cooling below: Tom C [This message has been edited by Tom C (edited February 19, 2004).] IP: Logged |

|

kuriakee Member Posts: 1 |

The rule of thumb for PE would be 0.025" - 0.035" greater in diameter than the nominal OD fo finished product (in this case it would be 0.435" - 0.445"). In this instance I would use 0.435", as the wall will cool quickly.  ------------------ IP: Logged |

All times are ET (US) | next newest topic | next oldest topic |

|

|

Contact Us | Feed Screw Designs

Powered by Infopop www.infopop.com © 2000

Ultimate Bulletin Board 5.45a