|

Author

|

Topic: Twin screw extrusion of POM

|

sergul

Member Posts: 4

From:Germany

Registered: Mar 2005

|

posted March 16, 2005 07:37 AM

posted March 16, 2005 07:37 AM

I am looking for a screw extruder configuration for a twin screw extruder for compounding of POM.

Anyone have any experience/idea, info. advice?IP: Logged |

Tom C

Moderator Posts: 492

From:Brodheadsville, PA USA

Registered: Jun 2001

|

posted March 16, 2005 11:13 AM

posted March 16, 2005 11:13 AM

What type of twin screw?Co- or counter? Intermeshing or not?

POM needs to be kept under about 210C melt temperature to prevent degradation.

Also a good stabilization package is required. ***While developing the process please make sure you have full-face respirators available to deal with the likely emmission of high levels of formaldehyde which is very dangerous!!!!*** ------------------

Best Regards, Tom Cunningham Extrusion Technical Services www.ExtrusionTechnicalServices.com IP: Logged |

sergul

Member Posts: 4

From:Germany

Registered: Mar 2005

|

posted March 30, 2005 07:46 AM

posted March 30, 2005 07:46 AM

Its co-rotating and intermeshing type twin screw extruder.

I am aware of these danger and because of this, I am working on the inhibition of POM degradation.

Another question:

which one of these elements produce higher shear ? 45 degree angled, 28 mm breite, triangle shaped ( 3-gangige) kneading disc or 45 degree angled, ellips shaped ( 2-gangige), 42 mm breite kneading disc? Thank you in advance...

Sergul quote:

Originally posted by Tom C:

What type of twin screw?Co- or counter? Intermeshing or not?

POM needs to be kept under about 210C melt temperature to prevent degradation.

Also a good stabilization package is required. ***While developing the process please make sure you have full-face respirators available to deal with the likely emmission of high levels of formaldehyde which is very dangerous!!!!***

IP: Logged |

Tom C

Moderator Posts: 492

From:Brodheadsville, PA USA

Registered: Jun 2001

|

posted March 30, 2005 11:05 AM

posted March 30, 2005 11:05 AM

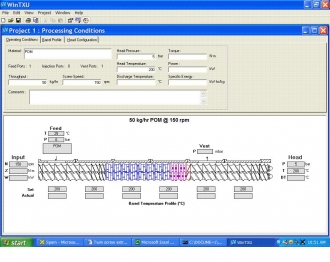

Sergul,Per PolyTech's TXS simulation program the stress while being processed by 3 lobe blocks is only slightly greater than the stress while being processed by 2 lobe blocks. A picture of the 3 lobe design used:  In either case the process temperature is difficult to control. ------------------

Best Regards, Tom Cunningham Extrusion Technical Services www.ExtrusionTechnicalServices.com IP: Logged |

sergul

Member Posts: 4

From:Germany

Registered: Mar 2005

|

posted March 31, 2005 03:18 AM

posted March 31, 2005 03:18 AM

One more question:What is the differrence between, neutral (90 degree)kneading blocks and standard-forwarding 45 degree kneading block in the manner of shearing? I have read that neutral kneading blocks having more mixing and more shearing effect than 45 degree forwarding kneading blocks. How come it can be so? I do not understand? Do you have any explanation? quote:

Originally posted by Tom C:

What type of twin screw?Co- or counter? Intermeshing or not?

POM needs to be kept under about 210C melt temperature to prevent degradation.

Also a good stabilization package is required. ***While developing the process please make sure you have full-face respirators available to deal with the likely emmission of high levels of formaldehyde which is very dangerous!!!!***

IP: Logged |

Tom C

Moderator Posts: 492

From:Brodheadsville, PA USA

Registered: Jun 2001

|

posted March 31, 2005 08:42 AM

posted March 31, 2005 08:42 AM

Sergul,The action of kneading blocks is somewhat complex. Some block sets with pitch can pump material. Neutral block sets of course do not pump material and stay full while processing. By the ability to pump material pitched block sets can pump themselves nearly empty. When the block pairs are nearly empty, mixing and shearing is thought to be much reduced. I would urge you to use forwarding block sets while melting resin. I have seen cases where neutral and reverse block sets have been employed too soon in a screw design resulting in equipment damage and excessive wear.

------------------

Best Regards, Tom Cunningham Extrusion Technical Services www.ExtrusionTechnicalServices.com IP: Logged |

sergul

Member Posts: 4

From:Germany

Registered: Mar 2005

|

posted March 31, 2005 09:04 AM

posted March 31, 2005 09:04 AM

Dear Tom, First of all, I thank you very much for the informations. I am still reading about the screw elements and I want to ask : What about the gear type mixing elements? Are they cause also shearing or they do only mixing? Is it logical to put 12 gear type mixing element without break or one needs to use conveying element or kneading blocks between them? How is the conveying efficiency of gear type mix elements? I have also triangular(three lobe) kneading blocks. First I had thought that, I would use it in melting zone, but do you think that,it is a good idea to use them in mixing zone with gear type mixing elements, instead of melting zone ? Because I have read, that these three lobe kneading blocks are good for the materials like POM, which are easily thermally degradable... Best regards,

Sergul

IP: Logged |

Tom C

Moderator Posts: 492

From:Brodheadsville, PA USA

Registered: Jun 2001

|

posted March 31, 2005 10:43 AM

posted March 31, 2005 10:43 AM

Sergul,Twin screw extruders are expensive to damage, and POM is dangerous to work with. Given this and the level of your knowledge I strongly recommend you employ the support of your twin screw vendor to help you develop your process. Learning extrusion generally takes years of hands on experience and asking the types of questions you are asking. In the USA I have an associate who gives a great seminar on twin screw technology. I suggest that you go to one of these seminars. Information on the seminar can be found at:

http://www.b4uextrude.com/pages/4/index.htm

Personally I am available for twin screw process consultation. Please email me if you would like more details. ------------------

Best Regards, Tom Cunningham Extrusion Technical Services www.ExtrusionTechnicalServices.com IP: Logged |

Contact Us | Feed Screw Designs

Powered by Infopop www.infopop.com © 2000

Ultimate Bulletin Board 5.45a

|