|

Author

|

Topic: High Sparkouts in circuit wire

|

BSouders

Member Posts: 3

From:Coffeyville, KS USA

Registered: Jun 2004

|

posted June 07, 2004 04:33 PM

posted June 07, 2004 04:33 PM

I work for a company that is producing circuit wire and building wire. With our smaller wire [(14-1, 12-1, 10-1 solid conductors) and (14-19, 12-19, and 10-19 stranded wire)] we are having a rise in sparkouts. We are extruding a PVC inner and a nylon jacket. We seem to keep getting pin holes in the insulation, which cause a sparkout and a sparkout causes scrap. Over the last year, the rate of sparkouts have risen significantly. We have been researching the problem and can not find any correlation between any changes in the process that we have made. We buy PVC resin from Georgia Gulf and color chips from Teknor color. We are trying to see if there has been some change in their products that can relate to our problem. IF ANYONE has ever seen this problem rise in wire and cable industry and found a way to correct it, please give me some advice. We are about to pull our hair out on things to try. ThanksBrian IP: Logged |

Tom C

Moderator Posts: 378

From:Brodheadsville, PA USA

Registered: Jun 2001

|

posted June 07, 2004 06:38 PM

posted June 07, 2004 06:38 PM

Are the holes in the PVC or Nylon?Do you coat in-line, or do you have a chance to test the PVC coat before putting on the Nylon? Tom C

IP: Logged |

BSouders

Member Posts: 3

From:Coffeyville, KS USA

Registered: Jun 2004

|

posted June 08, 2004 08:37 AM

posted June 08, 2004 08:37 AM

The holes are in the PVC. We coat with PVC, the 6 feet down the line, the Nylon is added on top of that. Brian IP: Logged |

Tom C

Moderator Posts: 378

From:Brodheadsville, PA USA

Registered: Jun 2001

|

posted June 08, 2004 11:40 AM

posted June 08, 2004 11:40 AM

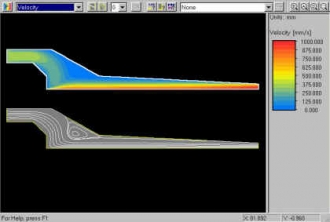

One of the more likely sources of your problem is un-melted resin. Typically as an extruder wears it's melting capability is reduced. The effect increaes with greater wear. Wear increases over time, so this may explain your increased problems over time.When the wire is coated the melt is accelerated in the die. Un-melted resin will not stretch like the surrounding melt and it is possible for a void to be created. I would contact the sponsor of the forum who provides extruder measurment equipment and extruder rebuilding services. If you would like a more thorough analysis, my company can provide a look inside the extruder through the use of simulation software. The amount of unmelted resin can be determined and screw designs can be developed to eliminate the problem. Additionally the wire coating process can be examined to see if the problem is occuring there. This is an example of a bad wire coating die design:  The circular lines show a dead area with high residence time. There are some other reasons for un-melted resin. Tell us more about your process. Has the line speed been increasing? Tom C www.ExtrusionTech.com

IP: Logged |

TomBlack

Moderator Posts: 53

From:

Registered: Jul 2002

|

posted September 30, 2004 06:18 PM

posted September 30, 2004 06:18 PM

I would agree w/ Tom C that non-melts may be a likely cause of grounding faults, however don't discount air entrapment. In either case, a new screw (and/or barrel) may help correct the problem. In the meantime, I'ld try lowering the upstream zone setting to create more pressure on the solid plug to help in expressing and entrapped air out through the feed hopper.------------------

Thomas Black

PPS, Inc. www.ppsincorp.com IP: Logged |

Contact Us | Feed Screw Designs

Powered by Infopop www.infopop.com © 2000

Ultimate Bulletin Board 5.45a

|