| next newest topic | next oldest topic |

| Author | Topic: Extrusion rate |

|

mbolanosd Member Posts: 2 |

How can one use a mathematical formula to determine the production rate in Kg/hr for different diameters and thickness in PVC pipe extrusion? Is there a formula for this? And if so, what variables are needed to apply such formula? IP: Logged |

|

Tom C Moderator Posts: 524 |

I'm not sure there is a simple formula. You should first consider some of the limitations of your process. Typically they are: 1) Avaialable KW motor power. Your limit will likely be about 3 KG/HR/(Installed KW). 2) Product cooling. Can you cool the product by the end of your line so that it hold its shape. 3) Interaction of the resin with the screw and die. Will the resin melt? Will it overheat and burn? Line trials or computer simulation can help determine the limits. ------------------

Tom Cunningham

Extrusion Technical Services www.ExtrusionTechnicalServices.com IP: Logged |

|

mbolanosd Member Posts: 2 |

Thanks Tom for your prompt response. What I am trying to figure out is a way to establish a mathematical Nominal Rate for each extruder and PVC pipe product for that extruder. Then make trial adjustments to see if we can obtain this mathematical Nominal Rate, and thus find the proper Nominal Rate and working parameters to use as our production target. Assuming that conditions 2) and 3) you mentioned are achievable, and that the compound used is the same for two products, is there a way to compare mathematically a 200 mm diameter and 2 MPa (14.8 mm minimum thickness) with a 160 mm diameter and 1.25 MPa (7.6 mm minimum thickness) for the same extruder (CM 80 connical twin screw)? Line trials alone, without a possible target to test against, considering the many operational conditions in a extruder causes considerable variability in production rates. then, How do we know that our line trials have obtain the correct Nominal Rate? Are we doomed to a heuristic approach? Where and how can we find a good computer simulator to accomplish this? Regards. IP: Logged |

|

2beeps Moderator Posts: 85 |

Based on the info I have, a CM-80 conical twin screw extruder equipped with a 75 HP drive can deliver up to 1300 lbs./hr of PVC pipe----and this assumes running at maximum (or close to)RPM, and flood feeding. This is based on the geometry (volume capability at 1.4+SpG) of the front barrel/screw--i.e.metering zone--area. Obviously, a heavier wall die (200mm Schedule 40)would be easier to acheive the maximum output rate than a thinner wall 200mm. or a thin wall 160 mm. pipe, assuming that a good quality pipe results. Rather than "hitting a toothpaste tube with your fist" (high output through a small orifice), you probably would need to back off somewhat on either the feed rate or screw RPM when running the thinner pipes. I am not aware of any mathematical solutions to this situation----in my own experience, it's been trial and error,with a little rationale thrown in. Of course all the above assumes you have a PVC formulation properly designed to run at high output rates on the CM-80!! IP: Logged |

|

Tom C Moderator Posts: 524 |

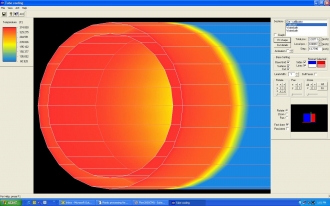

Based on Skip's input the output of a counter rotating twin screw running PVC pipe is 10 KG/HR/(Installed KW) rather than the 3 that had mentioned. This is likely due to the high density of the PVC formulation and the fact that rigid PVC is more "fused" than melted. I would use this as the ultimate target for your lines becuase you can always design away from cooling and die pressure problems. Pipe cooling is readily simulated using Compuplast's profile cooling simulation program. Screen shot below. Email me if you are further interested. Compuplast also has programs for the simulation of die flow and predicting pressure drop. I'm not aware of any commercial programs for the simulation of counter-rotating twin screws. ------------------

Tom Cunningham

Extrusion Technical Services www.ExtrusionTechnicalServices.com IP: Logged |

|

2beeps Moderator Posts: 85 |

One of the main features of the conical design, like the CM-80, is the very deep cut flights of the screws and the large rear zone diameter,both of which allow a larger amount of material entering the feed zone at a given RPM,hence the high output capability-----with a degree of compression built in due to the tapered barrel/screw configuration. Output calculations are made at the screw tips (i.e.80mm) IP: Logged |

All times are ET (US) | next newest topic | next oldest topic |

|

|

Contact Us | Feed Screw Designs

Powered by Infopop www.infopop.com © 2000

Ultimate Bulletin Board 5.45a